I am currently reading Make Your Own Guitar by Melvyn Hiscock. I am prepping myself as best I can for my first guitar build. This is hopefully the start of a Career. I’m hoping that over the next 10 years I can develop my skill at building guitars and make a Full Time career of it. It’s a tough business to get into especially competing with the Big dogs out there but I still believe there is a good market for Custom Built and Hand Built Guitars both Acoustic and electric. Like most things I have decided to just teach myself at least in the beginning. I’m sure I will take some classes down the road but for now it’s full steam ahead.

Tomorrow night I plan to go into the shop and finally knock out the post on Tuning a Miter Saw. I hope to have that up tomorrow night or Thursday. Once that post is done I will start on the WIWW Nightstand build and start the post with that. I want to break up each section into it’s own post so you have a step by step guide to building the nightstand. Sorry it has been taking so long on this. I know I got everyone all excited with the Series. I had some really great responses. April is about over and all of my commitments are mostly taken care of so I can spend some time focusing on the series and getting it done right for you.

On a side note…. In a jonesing for something woodworking I tackled a new type of woodworking tonight. Well not so much new as it was adapting some current skills into producing something else. I am excited about it and will post about that as well in the future but for now it is going to be a closely held secret. I think you will find it interesting as well. Tonight was mostly prototyping and figuring out how I wanted to do things. I still have a lot of figuring out to do on the project but think I am well on my way.

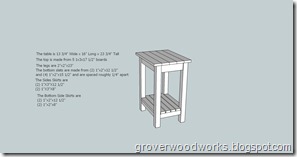

I also got to spend sometime in the shop with Grover Jr. tonight. We had a Parent/Child Project that we completed tonight from Home Depot. It was a little shelf kit with the number 20 Home Depot Car. Pretty neat. If you want to spend some quality time with you son or daughter I highly HIGHLY recommend the Lowes Build And Grow Program. I took Grover Jr. to one a few weeks back and we built a Kaleidoscope. There was just something very cool about spending sometime with him just the two of us sharing something that I love with him and seeing him enjoy it.

Here are some pictures after a successful morning of building.

He is a trip. We never could get him to stop making faces. I really totally so don’t know where he gets it from.

Have a Great Day!